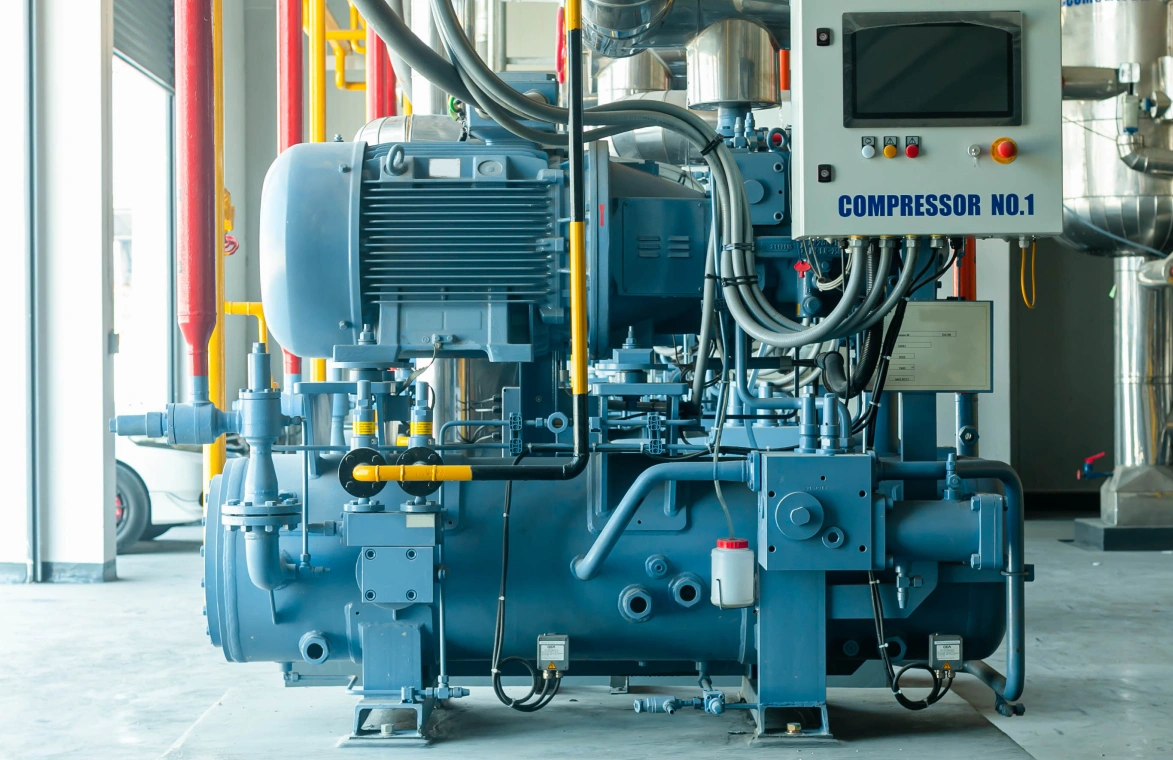

Agitator Case

In the agitator case, condition monitoring engineer detected vibrations and recommended maintenance. Despite initial repairs, further issues were identified. Ultimately, replacing the taper lock and bearings resolved the problem, saving $150,000.

Condition monitoring engineer observes vibration on agitator ODE, issues maintenance recommendation

Sheaves and belt replaced, but condition monitoring engineer calls out worsening sheave misalignment

The sheave pulley bore was found to be too big, and the ODE bearing was hot. Replaced taper lock and bearings. Issue resolved, $150k saved.

.gif)

.gif)